Hyundai Tucson: Automatic Transaxle Control System / Transaxle Control Module (TCM)

‚ÄĘ Monitoring the vehicle's operating conditions to determine the optimal gear setting.

‚ÄĘ Performing a gear change if the current gear setting differs from the identified optimal gear setting.

‚ÄĘ Determining the need for damper clutch (D/C) activation and engages the clutch accordingly.

‚ÄĘ Calculating the optimal line pressure level by constantly monitoring the torque level and adjusts the pressure accordingly.

‚ÄĘ Diagnosing the automatic transaxle for faults and failures.

1.TEST TCM GROUND CIRCUIT :Measure resistance between TCM and chassis ground using the backside of TCM harness connector as TCM side check point. If the problem is found, repair it.

Specification : Below 1‚Ą¶

2.TEST TCM CONNECTOR :Disconnect the TCM connector and visually check the ground terminals on TCM side and harness side for bent pins or poor contact pressure.

3.If any problems are not found in Step 1 and 2, the TCM could be faulty.If so, make sure there are no DTCs before replacing the TCM with a new one, and then check the vehicle again.If DTCs are found, examine this first before replacing TCM.

4.RE - TEST THE ORIGINAL TCM :Install the original TCM (may be broken) into a known-good vehicle and check the vehicle. If the problem occurs again, replace the original TCM with a new one.If problem does not occur, this is an intermittent problem (Refer to ‚ÄúIntermittent Problem Inspection Procedure‚ÄĚ in Basic Inspection Procedure).

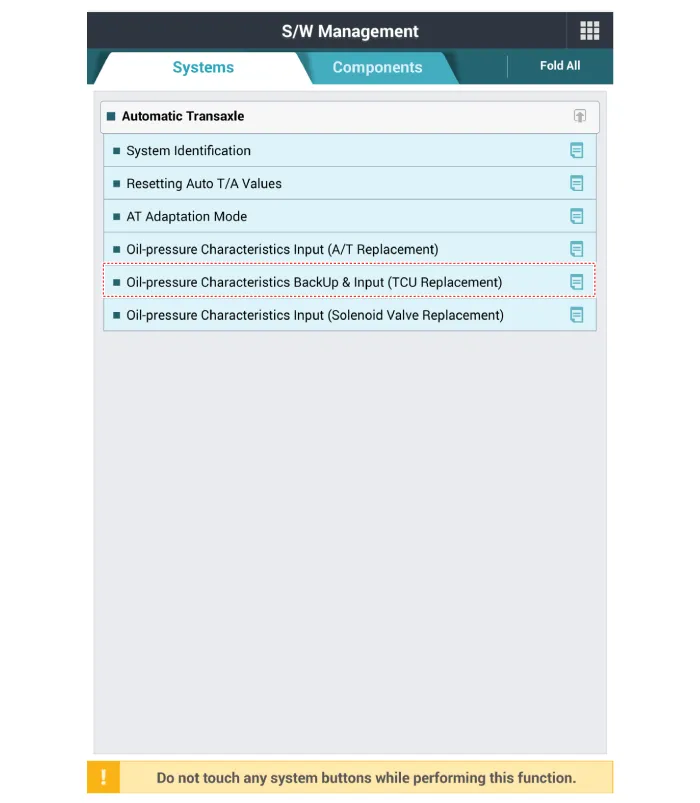

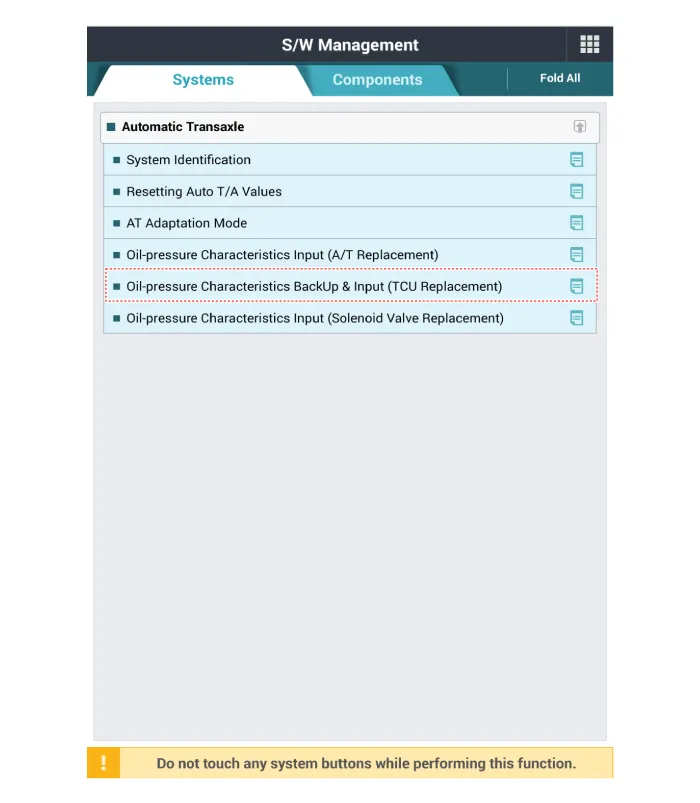

1.Perform the oil pressure characteristics backup procedure using the diagnostic tool when replacing with a new TCM.

2.Turn ignition switch OFF and disconnect the negative (-) battery cable.

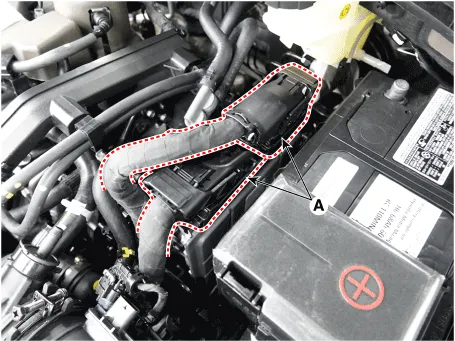

3.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air cleaner")

4.Remove the TCM.

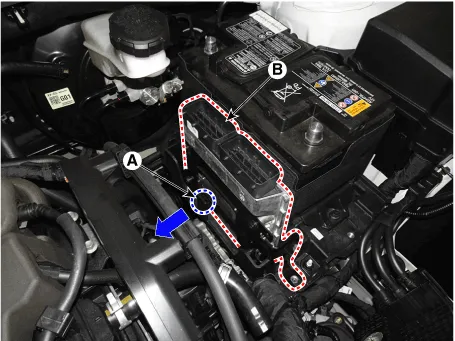

1)Disconnect the TCM connector (A).

2)Remove the ECM (A) after releasing the fixing hooks.

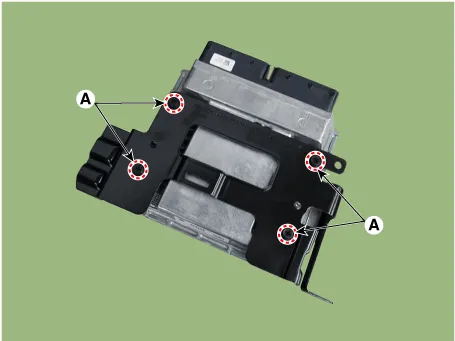

3)Remove the TCM after loosening the mounting nuts (A).

Tightening Torque : 6.9 - 8.8 N.m (0.7 - 0.9 kgf.m, 5.1 - 6.5 lb-ft)

1.To install, reverse the removal procedure.

2.Perform the oil pressure characteristics input procedure using the diagnotic tool when replacing with a new TCM.

‚ÄĘ Perform TCM learning after replacing the transaxle to prevent slow transaxle response, jerky acceleration and jerky startup.(Refer to Automatic Transaxle Control System - "Repair Procedures")

‚ÄĘ Perform the procedures related in the ECM after replacing the TCM.(Refer to Engine Control / Fuel System - "Engine Control Module (ECM)")

Repair procedures

Repair procedures

- Adjustment

TCM adaptive values learning

1.TCM adaptive values learning : When shift shock occurs or parts

related with the transaxle are replaced, TCM learning should be

performed.

2.In ...

SBW Control Unit(SCU)

SBW Control Unit(SCU)

- Component Location

1. Shift by wire Control Unit (SCU)

- Schematic Diagrams

PinFunctionPinFunction

1Power21-

2Ground22-

3H-CAN High23-

4H-CAN Low24-

5P-CAN High25-

6P-CAN Low26 ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Jack and Tools

1 Jack handle

2 Jack

3 Wheel nut wrench

The jack and wheel lug wrench are stored

in the luggage compartment under the

luggage box cover.

The jack is provided for emergency tire

changing only.

Turn the winged hold down bolt

counterclockwise to remove the spare

tire.

Store the sp ...

Hyundai Tucson (NX4) 2022-2026 Service Manual: Dynamic Damper

- Removal

1.Remove the front drive shaft.(Refer to Driveshaft Assembly - "Front Driveshaft")

2.Remove the trans axle side joint.(Refer to Driveshaft Assembly - "Transaxle Joint")

3.Remove the dynamic damper band (A, B) using driver (-).

‚ÄĘ When removing the dynamic d ...