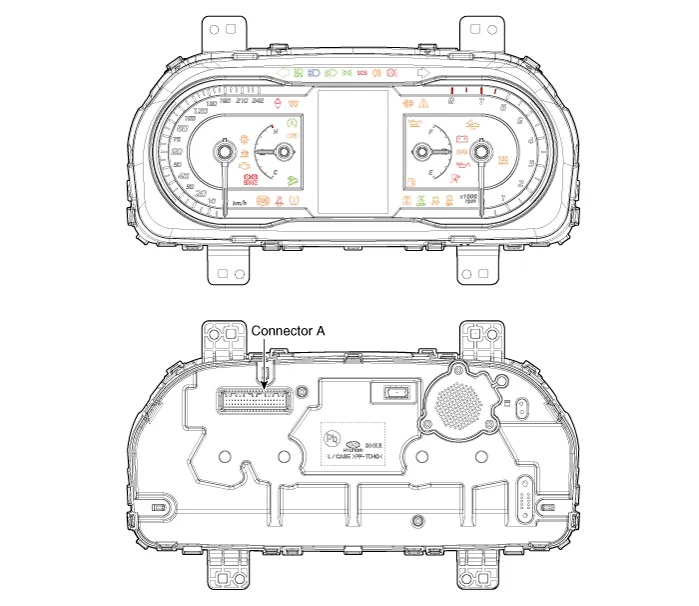

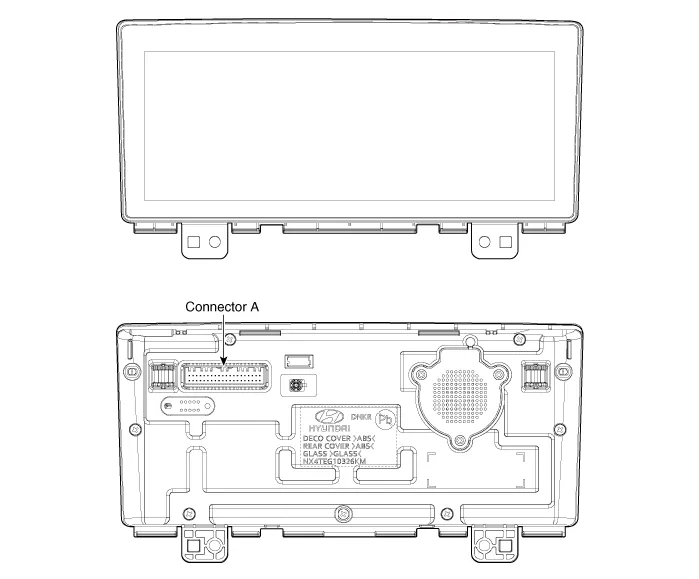

Hyundai Tucson: Indicators And Gauges / Instrument Cluster

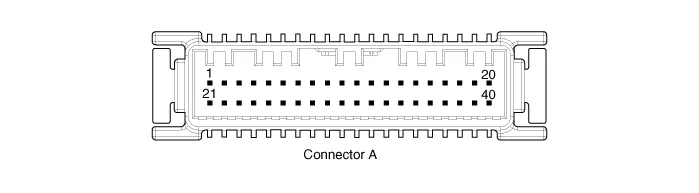

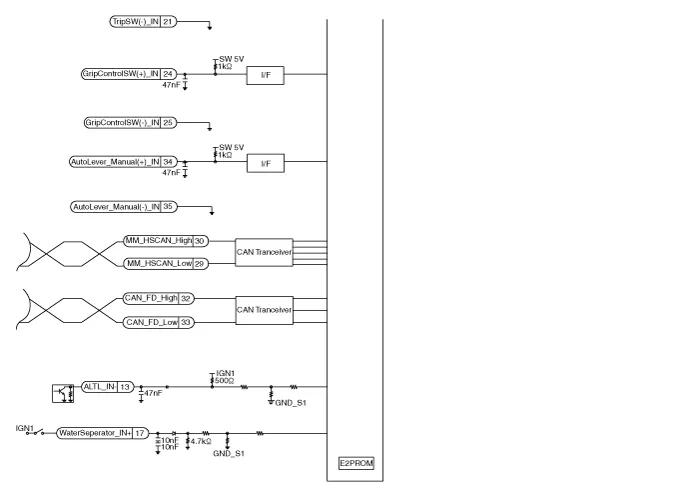

| No. | Connector A | No. | Connector |

| 1 | Ground 3 | 21 | Trip switch (-)_input |

| 2 | Illumination (-)_output | 22 | Trip switch 1 (+)_input |

| 3 | Rheostat switch (Down)_Input | 23 | Trip switch 2 (+)_input |

| 4 | Rheostat switch (Up)_Input | 24 | Grip control switch(+)_input |

| 5 | Dentent | 25 | Grip control switch(-)_input |

| 6 | P | 26 | - |

| 7 | R | 27 | - |

| 8 | N | 28 | - |

| 9 | D | 29 | M-CAN (Low) |

| 10 | S | 30 | M-CAN (High) |

| 11 | - | 31 | - |

| 12 | Vehicle speed_Output | 32 | CAN FD (High) |

| 13 | AlTL_Input | 33 | CAN FD (Low) |

| 14 | Fuel sender (+)_Input | 34 | Auto lever (+)_Input |

| 15 | - | 35 | Auto lever (-)_Input |

| 16 | Fuel sender (-)_Input | 36 | - |

| 17 | Water separate_Input | 37 | Ground 1 |

| 18 | Airbag (+)_Input | 38 | - |

| 19 | Oilpressure switch_Input | 39 | IGN 1 |

| 20 | - | 40 | Battery (+) |

1.Disconnect the negative (-) battery terminal.

2.Remove the cluster fascia panel.(Refer to Body - "Cluster Fascia Panel")

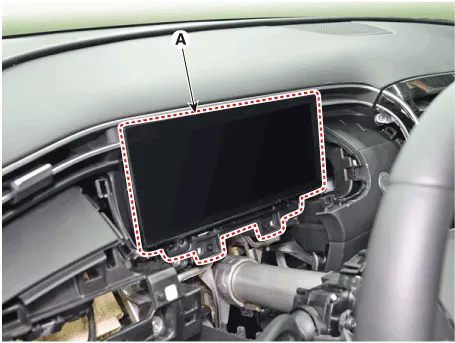

3.Remove the cluster (A) after loosening mounting screws.

4.Disconnect cluster connecters and then remove the cluster (A).

1.Install the cluster assembly.

2.Install the cluster facia panel.

3.Connect the negative (-) battery terminal.

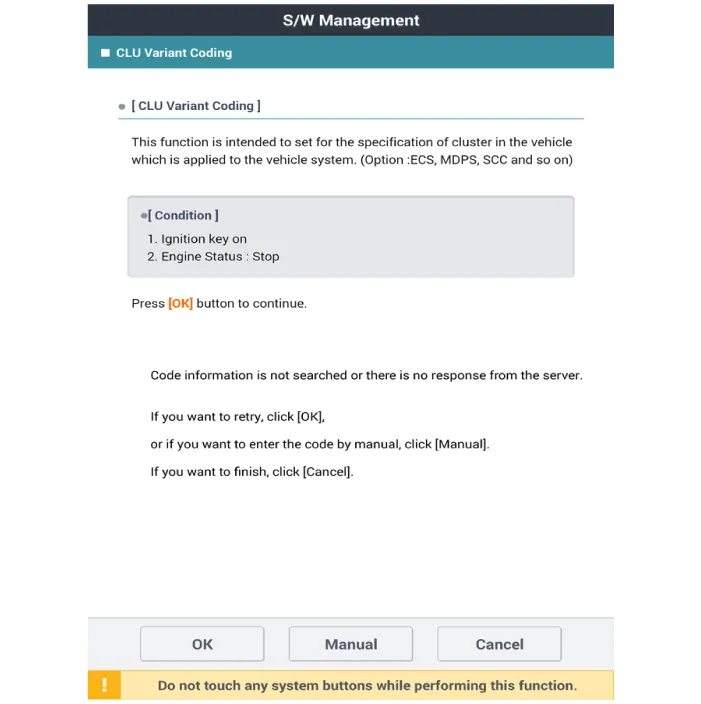

• Perform variant coding after exchanging the instrument cluster.

1.Check point (Warning indicator)

| No | Ref Symbol | Color | Name | Signal Input | Signal Control (Unit / Sensor) | Check Point | ||||

| 1 |

| Green | Turn Left | C-CAN | BCM |

| ||||

| 2 |

| Green | Turn Right | C-CAN | ||||||

| 3 |

| Green | Front Fog | C-CAN | BCM |

| ||||

| 4 |

| Blue | High Beam | C-CAN | BCM |

| ||||

| 5 |

| Green | Low Beam | C-CAN | BCM |

| ||||

| 6 |

| Green | Tail Lamp | C-CAN | BCM |

| ||||

| 7 |

| Green | Cruise | C-CAN | EMS |

| ||||

| 8 |

| Green | SET | C-CAN | EMS |

| ||||

| 9 |

| Red | Seat Belt | C-CAN | BCM |

| ||||

| 10 |

| Red | Air Bag | C-CAN | ACU |

| ||||

| 11 |

| Yellow | Trunk Open | C-CAN | BCM |

| ||||

| 12 |

| Red | Door Open | C-CAN | BCM |

| ||||

| 13 |

| Red | High Temperature | C-CAN | EMS |

| ||||

| 14 |

| Yellow | Immobilizer | C-CAN | SMK |

| ||||

| 15 |

| Yellow | ABS | C-CAN | ESC |

| ||||

| 16 |

| Yellow | EPB | C-CAN | EPB |

| ||||

| 17 |

| Yellow | ESC | C-CAN | ESC |

| ||||

| 18 |

| Yellow | ESC OFF | C-CAN | ESC |

| ||||

| 19 |

| Yellow | TPMS (Tread & Fail) | C-CAN | TPMS |

| ||||

| 20 |

| Yellow | Fuel Low | Hardwire | Fuel Sender |

| ||||

| 21 |

| Red | Parking Brake | C-CAN | BCM TCS EPB |

| ||||

| 22 |

| Yellow | Oil Pressure | Hardwire | Oil Pressure Sensor |

| ||||

| 23 |

| Red | Battery Charge | Hardwire | Battery Sensor |

| ||||

| 24 |

| Yellow | Check Engine | C-CAN | EMS |

| ||||

| 25 |

| Yellow | Low Washer | Hardwire | Water Level Sensor |

| ||||

| 26 |

| Green | AUTOHOLD (Green) | C-CAN | ESC |

| ||||

| Yellow | AUTOHOLD (Yellow) | C-CAN | ESC |

| |||||

| White | AUTOHOLD (White) | C-CAN | ESC |

| |||||

| 27 |

| Green White Yellow | LDWS | C-CAN | LDWS |

| ||||

| 28 |

| Green | Active ECO | Hardwire | ECO ON/OFF Switch |

| ||||

| 29 |

| Yellow | 4WD Diagnosis | C-CAN | 4WD Unit |

| ||||

| 30 |

| Yellow | 4WD LOCK | C-CAN | 4WD ECU |

| ||||

| 31 |

| Yellow | Glow | C-CAN | Glow Plug |

| ||||

| 32 |

| Red | EPS | C-CAN | EPS Unit |

| ||||

| 33 |

| Red | Water Seperator | C-CAN | Fuel filter water seperator sensor |

| ||||

| 34 |

| Green Yellow | DBC | C-CAN | TCU |

|

2.Check point (Gauge)

| No | Name | Signal Input | Signal Control (Unit/Sensor) | Check Point | ||||

| 1 | Speedometer | C-CAN | TCU, ABS |

| ||||

| 2 | Tachometer | C-CAN | EMS |

| ||||

| 3 | Cooling water temperature | C-CAN | EMS |

| ||||

| 4 | Fuel | Hardwire | Fuel sender |

|

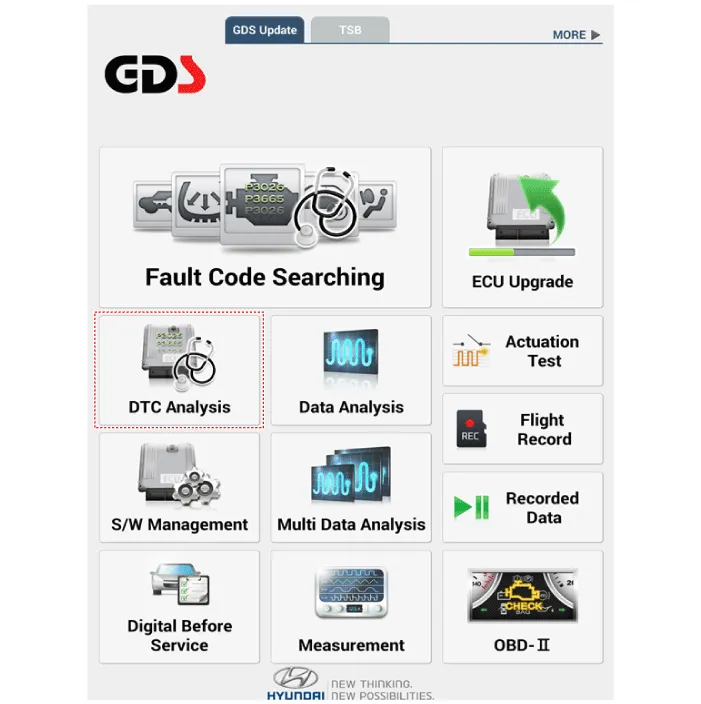

1.In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system.The diagnostic system provides the following information.

(1)Fault Code Searching : Checking failure and code number (DTC)

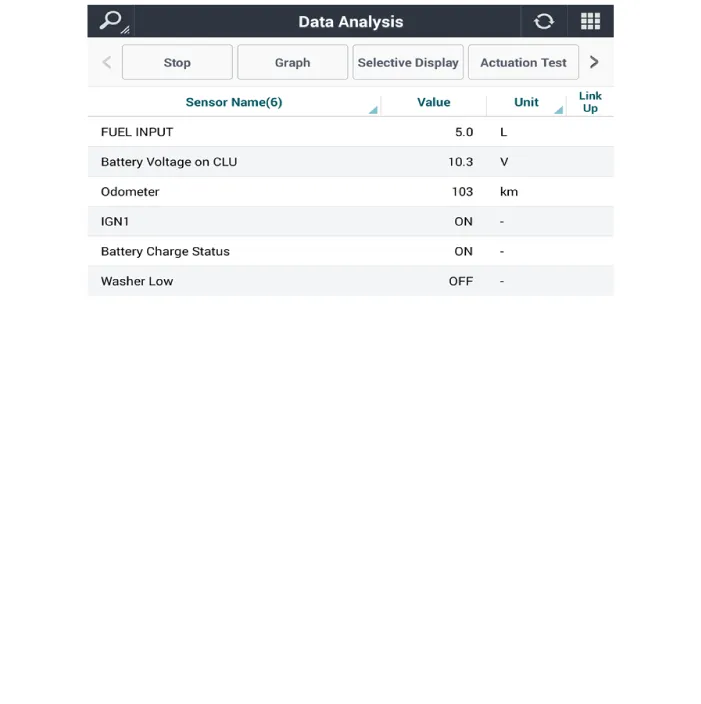

(2)Data Analysis : Checking the system input/output data state

(3)Actuation test : Checking the system operation condition

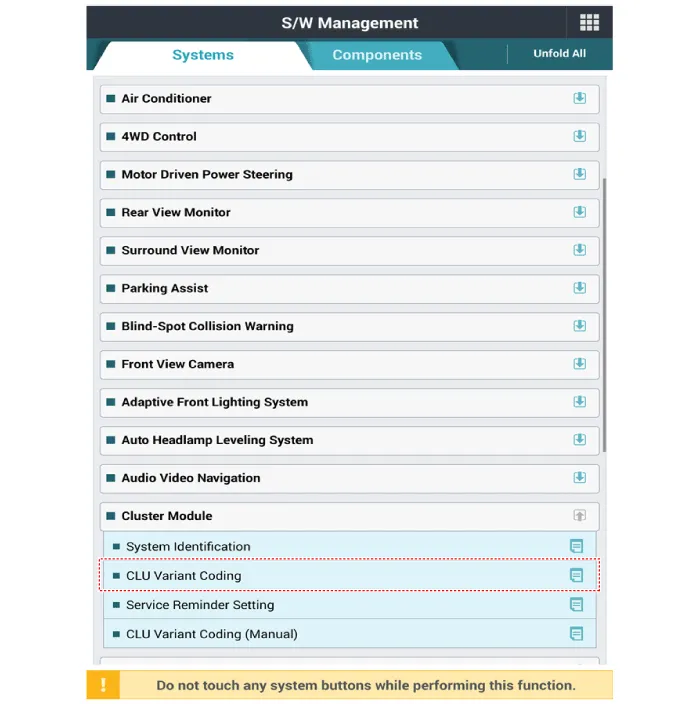

(4)S/W Management : Controlling other features including system option setting and zero point adjustment

2.If diagnose the vehicle by diagnostic tool, select "DTC Analysis" and "Vehicle".

3.If check current status, select the "Data Analysis" and "Car model".

4.Select the 'CLU' to search the current state of the input/output data.

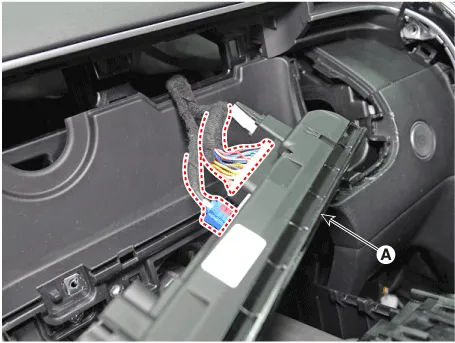

1.Connect the cable of diagnostic tool to the data link connector in driver side crash pad lower panel.

2.Select the 'S/W Management' and 'Car model'.

3.Select the 'Cluster Module' and 'CLU Variant Coding'.

Troubleshooting

Troubleshooting

- Troubleshooting

Error ItemFailure SymptomInspection Items Detailed Inspections Relevant Parts/Components

Screen displayLCD-TFT screen does not turn on1)Connector attachments

2)Components

1 ...

Power Door Locks

Power Door Locks

Components and Components Location

- Component Location

1. Liftgate lock actuator2. Driver door moudle (DDM)3. Front door lock actuator4. Rear door lock actuator

Power Door Lock Actuators

- ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Service Manual: Power Seat Control Switch

- Circuit Diagram

Driver Power Seat Swtich

Passenger Power Seat Swtich

- Inspection

1.With the power seat switch in each position, make sure that

continuity exists between the terminals below. If continuity is not as

specified, replace the power seat switch.

Driver Power Seat C ...

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Side airbags

The side airbags are designed to deploy

during certain side impact collisions,

depending on the crash severity.

The side airbags on both sides of the

vehicle are designed to deploy when a

rollover is detected by a rollover sensor.

The side airbags are not designed to

deploy in all si ...