Hyundai Tucson: Engine Control System / E-CVVT Motor

| Item | Specification |

| Motor Power (Max.) | 125W / 12V (Room Temperature) |

| Control Current | Max. 48.1A (Room Temperature) |

1.Remove the engine mounting bracket.(Refer to Engine Mechanical System - "Engine Mounting")

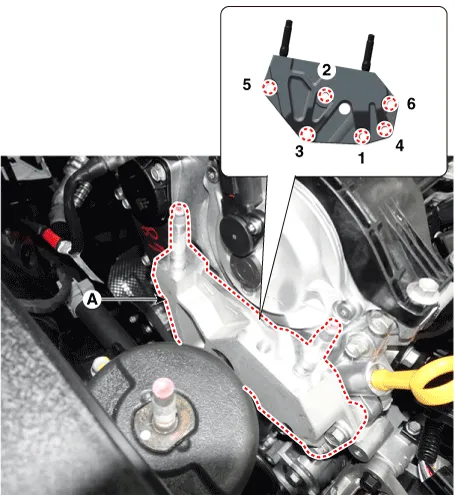

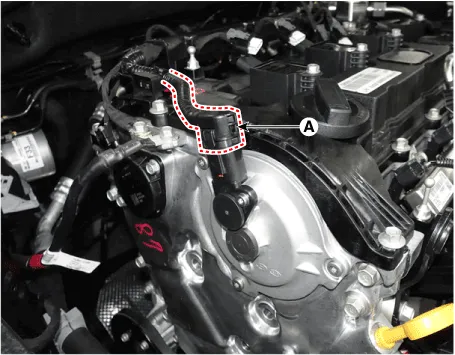

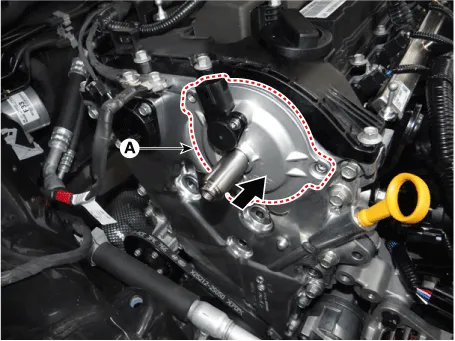

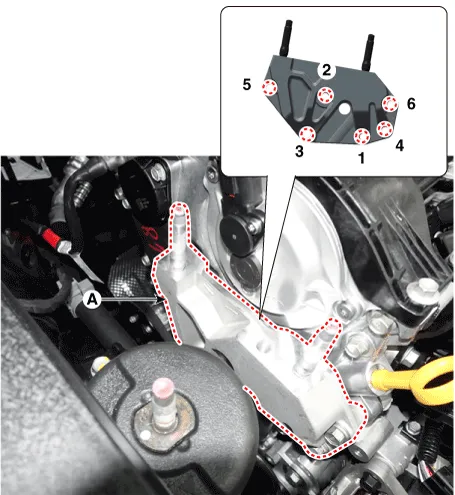

2.Remove the engine support bracket (A) after loosening the mounting bolt.

• Loosen the bolts in the sequence shown (6→5→4→3→2→1).

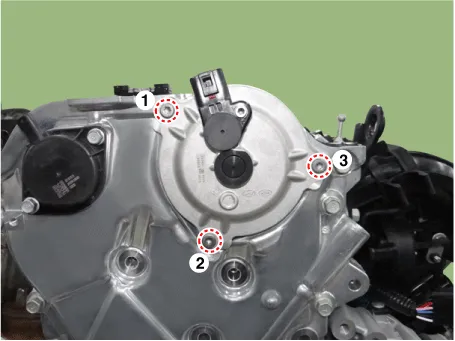

3.Remove the E-CVVT cover connector (A).

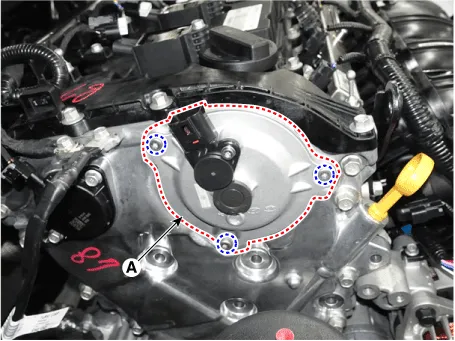

4.Remove the E-CVVT cover (A) after loosening the mounting bolt.

• Take care avoid external force to the brush after removing the cover.

• Remove after 30 minutes of switching "OFF" the ignition to drain out the oil inside the E-CVVT motor plug.

1.Remove the timing chain.(Refer to Engine Mechanical System - "Timing Chain")

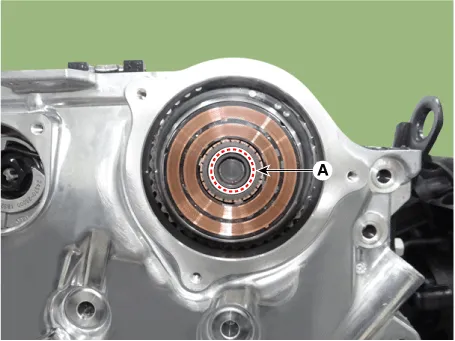

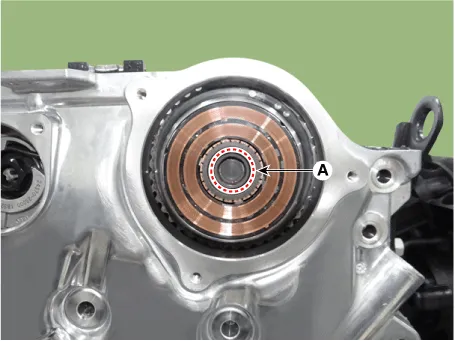

2.Remove the center of the E-CVVT motor plug (A) by breakig it.

• Do not tilt the front of engine (timing chain cover side) downward as residual oil may flow out during E-CVVT motor plug removal.

• If oil flows out during E-CVVT motor plug removal, wipe off immediately and block the motor shaft inlet with a clean towel.

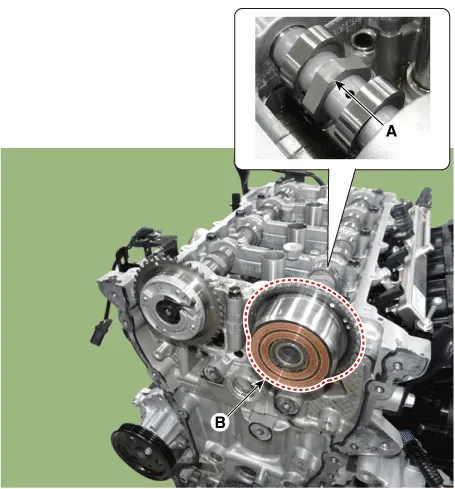

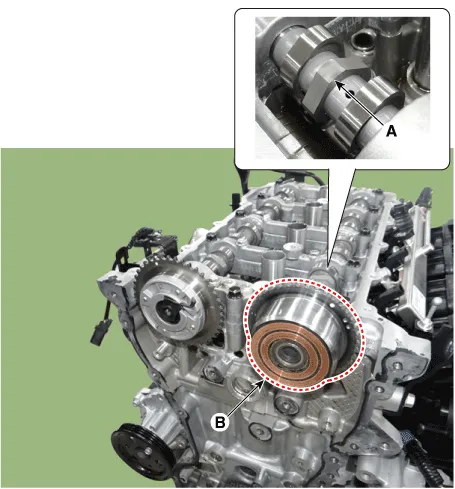

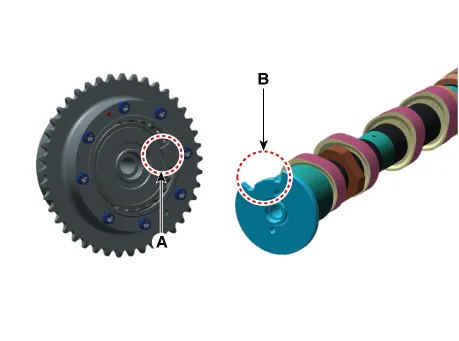

3.Fix the camshaft part (A) using the wrench, and then remove the E-CVVT motor (B) after loosening the mounting bolt.

1.Remove the center of the E-CVVT motor plug (A) by breakig it.

• Remove after 30 minutes of switching "OFF" the ignition to drain out the oil inside the E-CVVT motor plug.

• Do not tilt the front of engine (timing chain cover side) downward as residual oil may flow out during E-CVVT motor plug removal.

• If oil flows out during E-CVVT motor plug removal, wipe off immediately and block the motor shaft inlet with a clean towel.

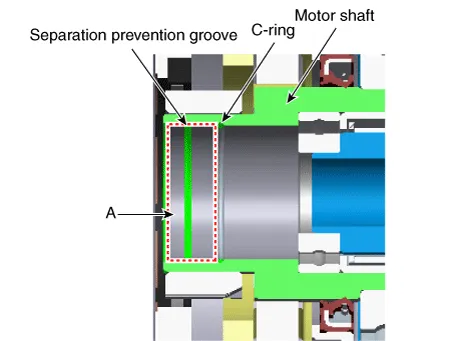

2.Clean the E-CVVT motor plug mounting surface (A) with oil cleaner.

• If the surface is not cleaned, E-CVVT motor plug may be separated due to diminished separation force from residual oil.

• When spraying oil cleaner, block around the motor shaft inlet and rotor gap with a clean towel to prevent inflow of oil from flowing into the rotor gap.

3.When reusing the E-CVVT cover, inspect the below items.

(1)If there is sign of leakage from inside the E-CVVT cover, replace it with a new one.

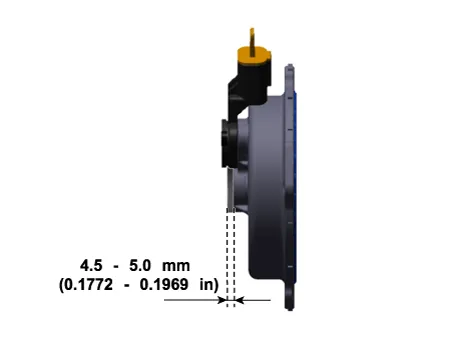

(2)Check for worn connector brush (A).

Specification : Over 5 mm (0.1969 in.)

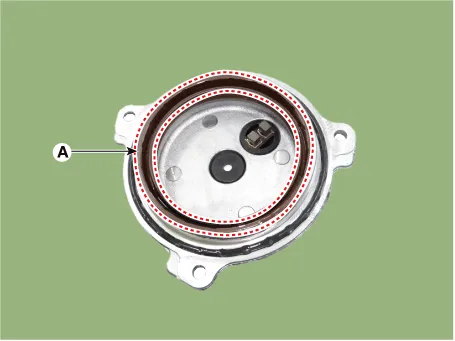

(3)Check for damaged oil seal (A) and replace any damaged E-CVVT cover with a new one.

(4)After inspecting E-CVVT, if no problem is found, replace the o-ring (A) with a new one.

4.Install the E-CVVT cover.

(1)Apply engine oil on oil seal lip (A).

• When applying oil, keep the connector brush (A) clean from foreign materials.

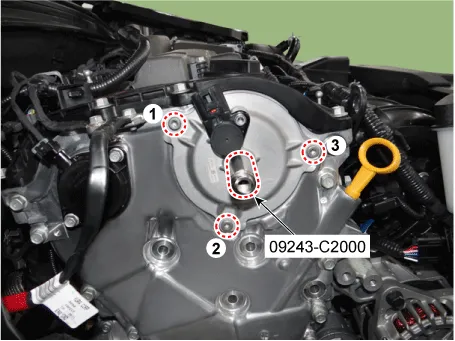

(2)Insert SST (09243-C2000) into the E-CVVT motor shaft.

• Correctly mount SST onto the motor shaft.

(3)Slowly push the E-CVVT cover (A) until it is flush with the timing chain cover surface.

• Installing the E-CVVT cover without SST may cause oil leakage inside the E-CVVT motor due to damaged or separated E-CVVT oil seal.

(4)Pre-tighten the bolts in the below sequence, and then remove the SST (09243-C2000).

Tightening torque :1.0 - 2.0 N.m (0.1 - 0.2 kgf.m, 0.7 - 1.4 lb-ft)

(5)Tighten the bolts to the specified torque in the sequence below.

Tightening torque :9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

5.Install the E-CVVT plug.

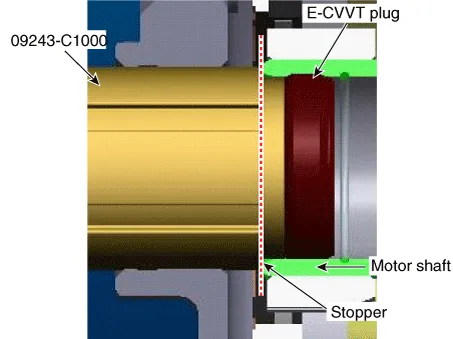

(1)By using SST (09243-C2000), insert the plug into the E-CVVT cover hole.

(2)Mount the stopper of SST so that it sits at the end of E-CVVT motor shaft.

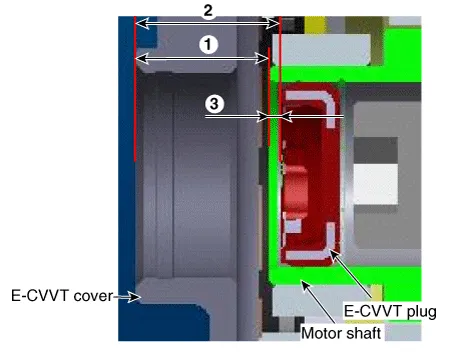

6.Inspect the pressed depth of E-CVVT plug.

(1)By using a steel ruler, measure the distance from E-CVVT cover center boss to the end of motor shaft (â‘ ).

(2)By using a steel ruler, measure the distance from E-CVVT cover center boss to the end of E-CVVT plug (②).

(3)Calculate the pressed depth (③) of motor plug.If out of specification, reinstall after replacing the E-CVVT plug with a new one.

Pressed depth : ③ = ② - ①Specification : 1.1 - 2.1 mm (0.0433 - 0.0827 in.)

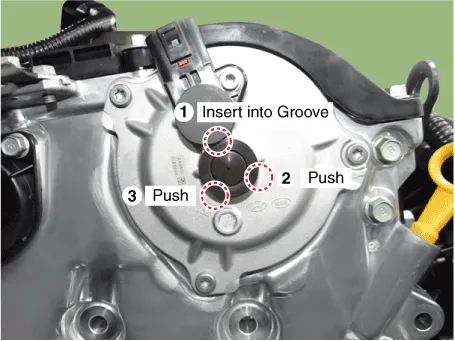

7.Insert the E-CVVT cover plug so that the protrusion reach to E-CVVT cover groove correctly.

• Check how much protrude after installing the E-CVVT plug.

• Be careful that the plug is not inserted inside E-CVVT cover beyond the regulated range.

8.Install the engine support bracket (A).

Tightening torque :39.2 - 44.1 N.m (4.0 - 4.5 kgf.m, 28.9 - 32.5 lb-ft)

(1)Pre-tighten the bolts in the sequence (1→2→3).

(2)Turn the bracket counterclockwise and then tightening the bolt 1.

(3)And then tighten the bolt in the sequence (2→3→4→5→6).

9.Install the engine mounting bracket.(Refer to Engine Mechanical System - "Engine Mounting")

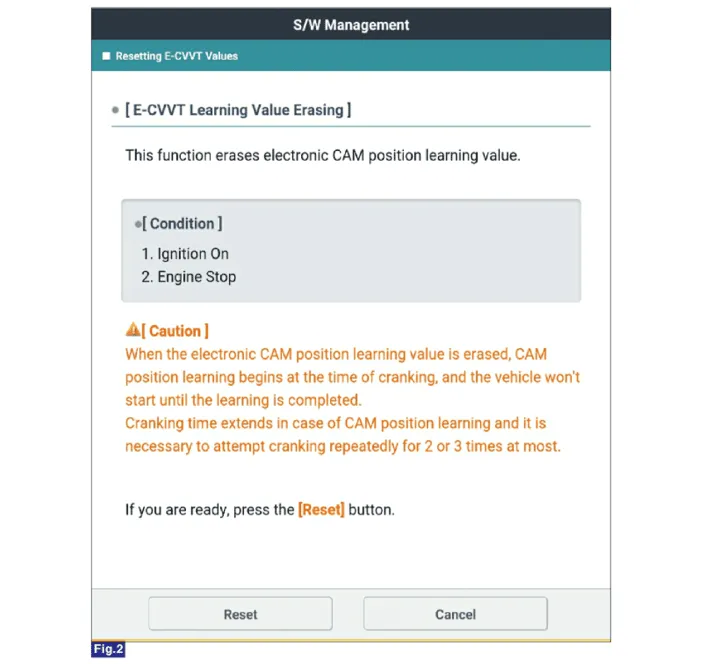

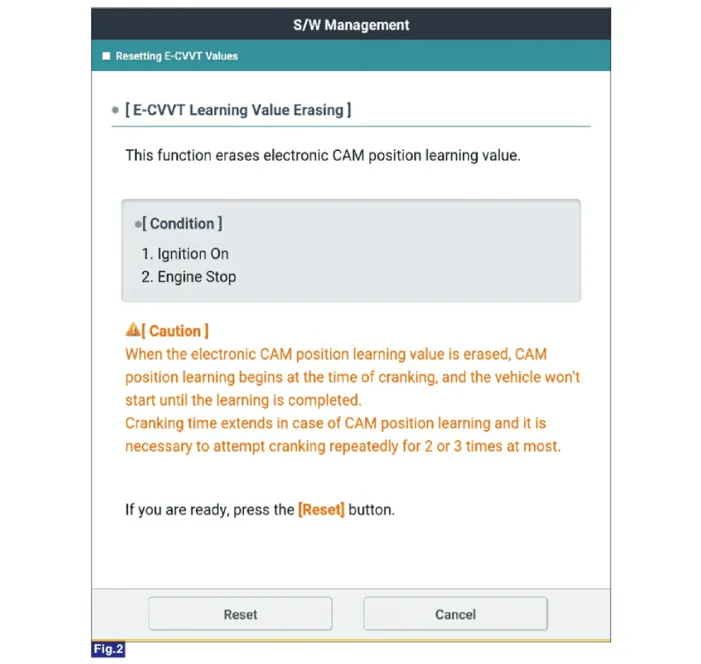

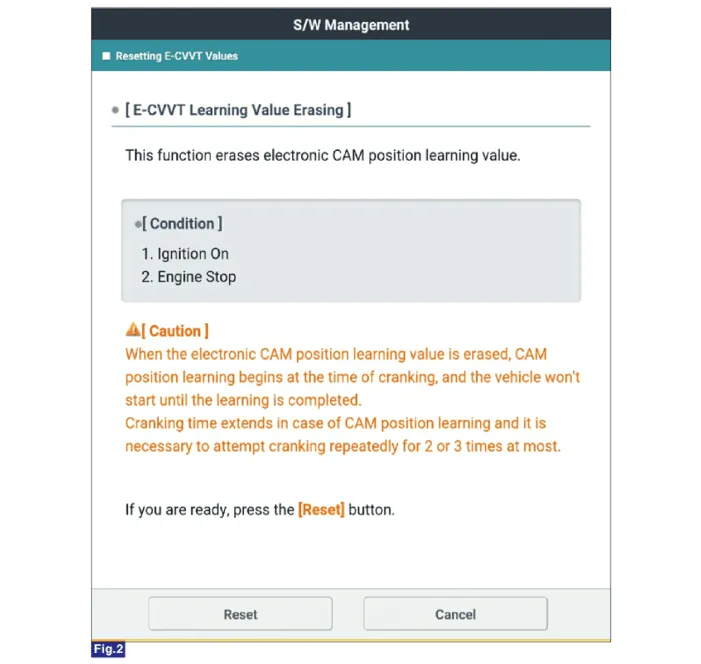

10.Perform the E-CVVT learning value erasing using the diagnosis tool.

• After replacing or remounting the E-CVVT assembly, be sure to reset the learned value from the additional feature menu on the diagnostic device.

• When the learned value for electronic cam position is erased, start learning the cam position while cranking. The engine can start once this is completed.

• Cranking should be repeated for up to 2-3 times to complete learning.

1.Install the E-CVVT motor (A).

Tightening torque :73.5 - 83.4 N.m (7.5 - 8.5 kgf.m, 54.2 - 61.5 lb-ft)

2.Fix the camshaft part (A) using the wrench, and then remove the E-CVVT motor (B) after loosening the mounting bolt.

• Tighten the bolts with the E-CVVT stopper (A) and the camshaft slot (B) in contact.

3.Install the timing chain.(Refer to Engine Mechanical System - "Timing Chain")

4.Perform the E-CVVT learning value erasing using the diagnosis tool.

• After replacing or remounting the E-CVVT assembly, be sure to reset the learned value from the additional feature menu on the diagnostic device.

• When the learned value for electronic cam position is erased, start learning the cam position while cranking. The engine can start once this is completed.

• Cranking should be repeated for up to 2-3 times to complete learning.

• After replacing or remounting the E-CVVT assembly, be sure to reset the learned value from the additional feature menu on the diagnostic device.

• When the learned value for electronic cam position is erased, start learning the cam position while cranking. The engine can start once this is completed.

• Cranking should be repeated for up to 2-3 times to complete learning.

Variable Intake Solenoid (VIS) Valve

Variable Intake Solenoid (VIS) Valve

- Description

Variable Intake manifold Solenoid (VIS) valve is installed on the

intake manifold. The VIS valve controls the vacuum modulator which

activates a valve in the intake manifold. The ...

Canister Close Valve (CCV)

Canister Close Valve (CCV)

- Description

Canister Close Valve (CCV) is normally open and is installed on the

canister ventilation line. It seals evaporative emission control system

by shutting the canister from the atmos ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Reverse Parking Collision-Avoidance Assist (PCA)

Reverse Parking Collision-Avoidance

Assist uses the wide-rear view camera

and rear ultrasonic sensors to help detect

pedestrians or objects when backing

up. The function may warn you or assist

you with braking to help reduce the

possibility of a collision when backing

up.

Information

...

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: EPB malfunction

Electronic Parking Brake (EPB) warning

light illuminates if the ignition switch is

in the ON position and goes off in about

3 seconds if the system is operating

normally.

If the EPB warning light remains on,

comes on while driving, or does not

come on when the ignition switch is ON,

t ...