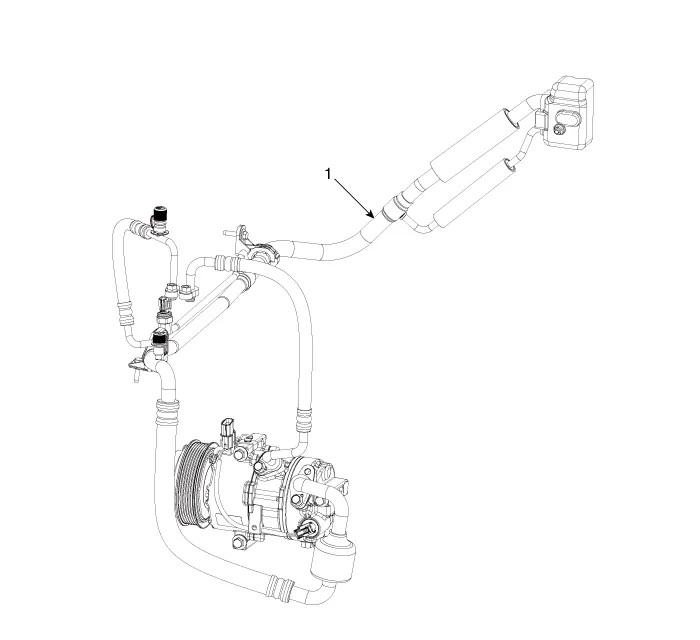

Hyundai Tucson: Air Conditioning System / Refrigerant Line

1. Suction & Liquid Pipe Assembly

1.If a compressor is available, the air conditioner is operated for a few minutes in the engine idle state and then the engine is stopped.

2.Disconnect the negative (-) battery terminal.

3.Recover the refrigerant with a recovery/charging station.(Refer to Air conditioning System - "Repair procedures")

4.Remove the engine cover.(Refer to Engine Mechanical System - "Engine Cover")

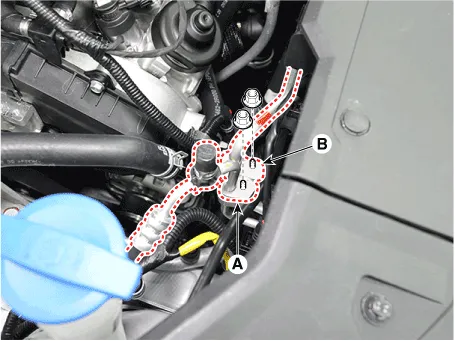

5.Loosen the mounting nut and separate the expansion valve cover (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

6.Loosen the mounting bolts and separate the expansion valve (A) fron evaporator core.

Tightening torque : 21.6 - 32.4 N.m (2.2 - 3.3 kgf.m, 15.9 - 23.9 lb-ft)

7.Loosen the mounting nuts and separate the suction line (A), discharge line (B).

Tightening torque : 19.6 - 23.5 N.m (2.0 - 2.4 kgf.m, 14.5 - 17.4 lb-ft)

8.Disconnect the APT sensor connector (A).

9.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

10.Remove the engine mounting braket.(Refer to Engine Mechanical System - "Engine Mounting")

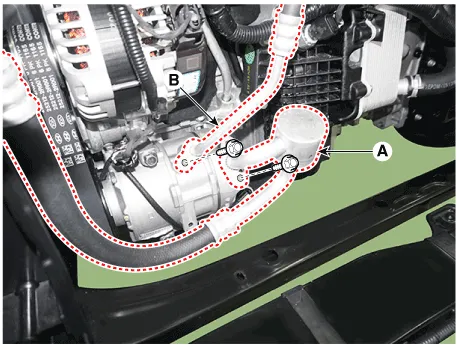

11.Separate the compressor suction line (A) and discharge line (B) connection nuts and disconnect the line.

Tightening torque : 21.6 - 32.4 N.m (2.2 - 3.3 kgf.m, 15.9 - 23.9 lb-ft)

• Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.(Refer to General Information - "Lift and Support Points")

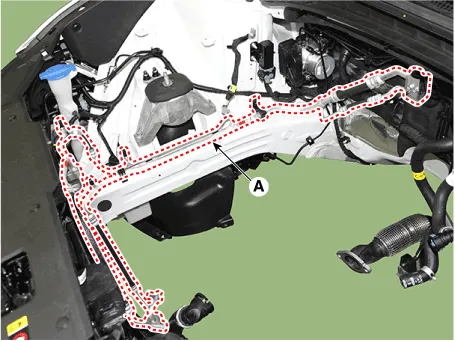

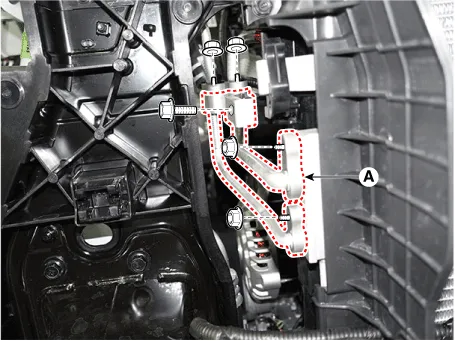

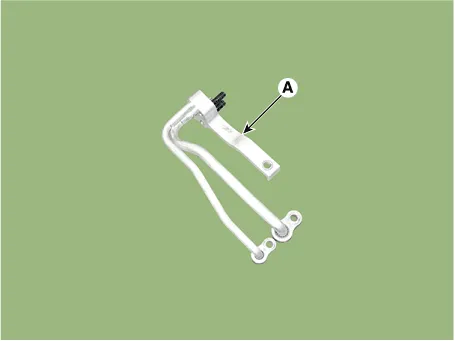

12.Loosen the mounting bolt and remove the Front suction & Liquid pipe assembly (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

13.Install in the reverse order of removal.

• Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

• Tighten the bolt or nut joint to the specified torque.

• Using a gas leak detector, check for refrigerant leakage.

• Evacuate air in the refrigeration system and charge system with refrigerant.

Capacity : R-1234yf : 550 ± 25g (17.7 ± 0.88oz)R-134a : 550 ± 25g (17.68 ± 0.88oz)

1.Remove the front bumper assembly.(Refer to Body (Interior and Exterior) - "Front Bumper Assembly")

2.Recover the refrigerant with a recovery/charging station.(Refer to Air conditioning System - "Repair procedures")

3.Loosen the mounting nuts, and then disconnect the liquid line (A) from the condenser.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

4.Install in the reverse order of removal.

• Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

• Tighten the bolt or nut joint to the specified torque.

• Using a gas leak detector, check for refrigerant leakage.

• Evacuate air in the refrigeration system and charge system with refrigerant.

Capacity : R-1234yf : 550 ± 25g (17.7 ± 0.88oz)R-134a : 550 ± 25g (17.68 ± 0.88oz)

Compressor oil

Compressor oil

- Oil Specification

1.The R-134a or R-1234yf system requires synthetic (PAG) compressor

oil whereas the R-12 system requires mineral compressor oil. The two

oils must never be mixed.

2.Compre ...

Compressor

Compressor

- Description

The compressor is the power unit of the A/C system.It is located on the

side of engine block and driven by a V-belt of the engine.The

compressor changes low pressure and low tempe ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Service Manual: Troubleshooting

- Trouble shooting

Area of leakage occuringAreaType

①Connecting part/under part of transfer case② Connecting part of transmission

[A]

①Connecting part/under part of transfer case② Connecting part of transmission③ Assembly part of drive shaft

[B]

SymptomExpected causeCountermeasur ...

Hyundai Tucson (NX4) 2022-2026 Service Manual: Front Washer Motor

- Inspection

Front and Rear Washer Motor

1.With the washer motor connected to the reservoir tank, fill the reservoir tank with water.

• Before filling the reservoir tank with water, check the filter

for foreign material or contamination. if necessary, clean the filter.

...