Hyundai Tucson: Engine Control System / Injector

| Item | Specification |

| Coil Resistance (Ω) | 11.4 - 12.6 |

| Item | Specification |

| Coil Resistance (Ω) | 1.43 - 1.58 |

1.In the engine control system, failure can be quickly diagnosed by using the diagnosis tool.

(1)Self diagnosis : Checking failure and code number (DTC).

(2)Current data : Checking the system input/output data state.

(3)Actuation test : Checking the system operation condition.

(4)Additional function : Controlling other features including system option setting and zero point adjustment.

1.Turn the ignition switch OFF.

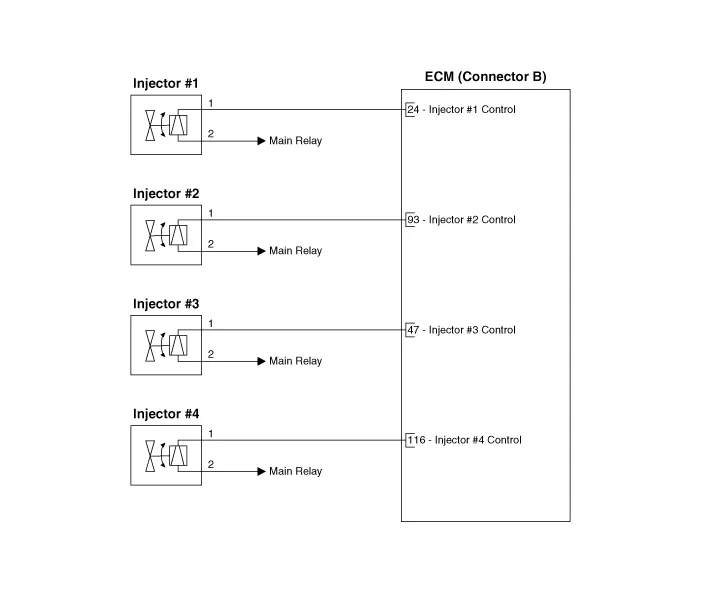

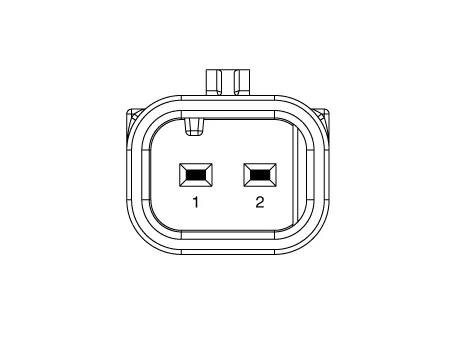

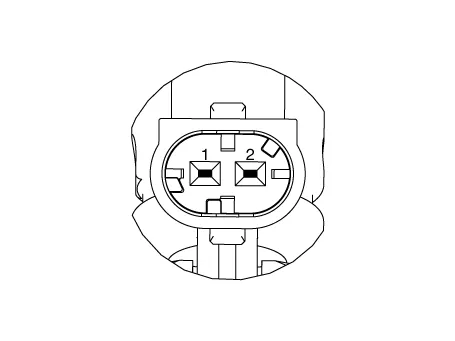

2.Disconnect the injector connector.

3.Check that the resistance is within the specification.

Specification : Refer to "Specification"

1.Release the residual pressure in fuel line.(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line")

2.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

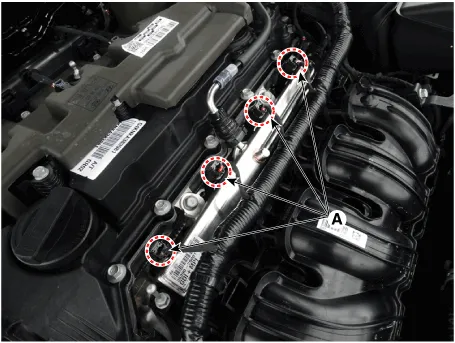

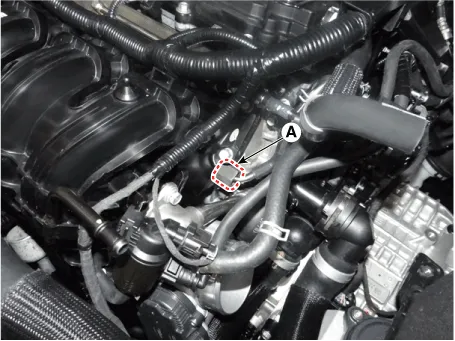

3.Disconnect the injector connector (A).

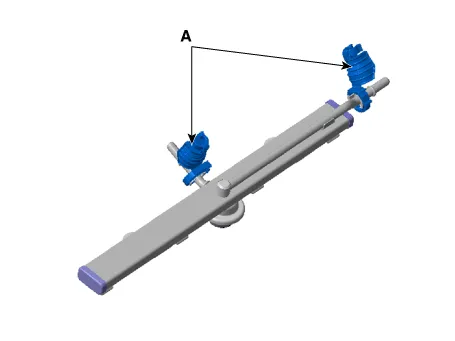

4.Disconnect the fuel feed quick-connector (A).

• Open the clamp cover (A) before disconnecting the quick-connector. (If the clip is applied)

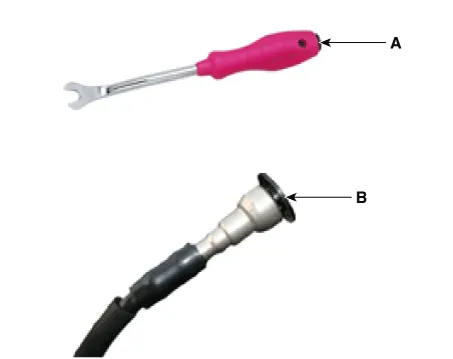

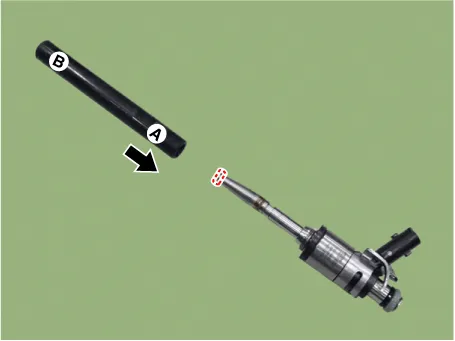

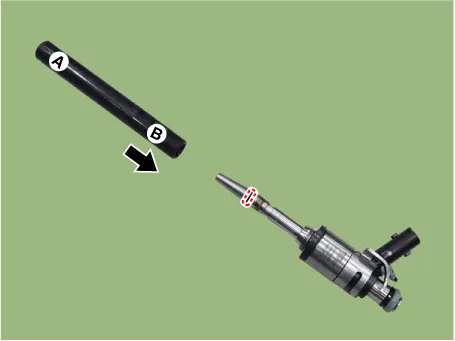

• When removing the quick-connnector with the clip removing tool (A), be careful not to damage the plastic clip (B).

• If the clip is damaged, it can cause a fuel leak due to bad connection and could result in a fire.

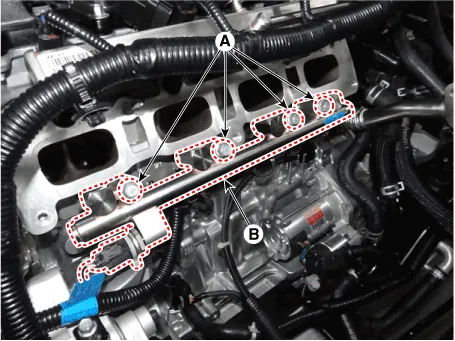

5.Remove the delivery pipe after loosening the mounting bolt (A).

Tightening Torque :18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.3 lb-ft)

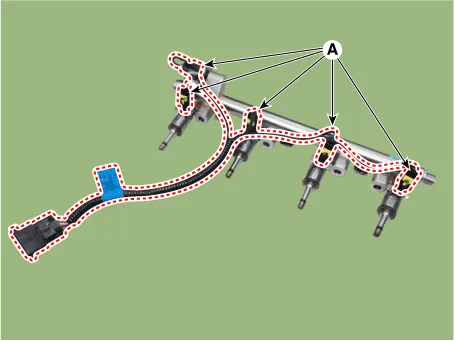

6.Remove the injector from the delivery pipe (A) after releasing the fixing clip both side as shown below.

1.Release the residual pressure in fuel line.(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line")

2.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

3.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air Cleaner")

4.Remove the intake manifold.(Refer to Engnie Mechanical System - "Intake Manifold")

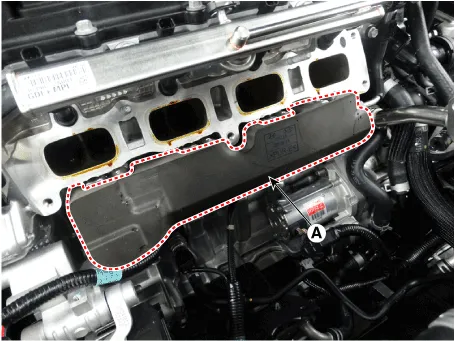

5.Remove the injector foam (A).

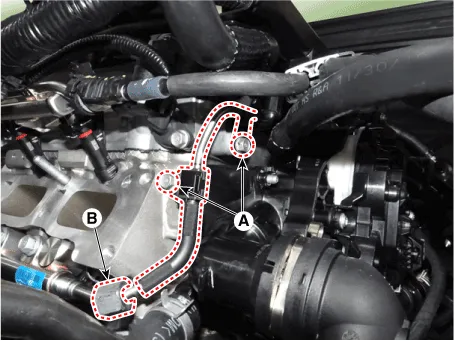

6.Loosen the high pressure fuel pipe bracket mounting bolt (A) and then loosen the flange nut (B,C).

Tightening Torque A : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)B, C : 26.5 - 32.4 N.m (2.7 - 3.3 kgf.m, 19.5 - 23.9 lb-ft)

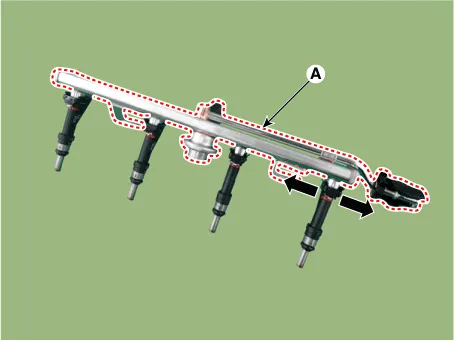

7.Loosen the mountin bolt (A) and then remove the delivery pipe & injector assembly (B).

Tightening Torque :18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.3 lb-ft)

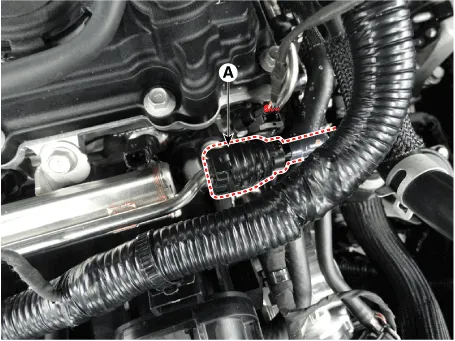

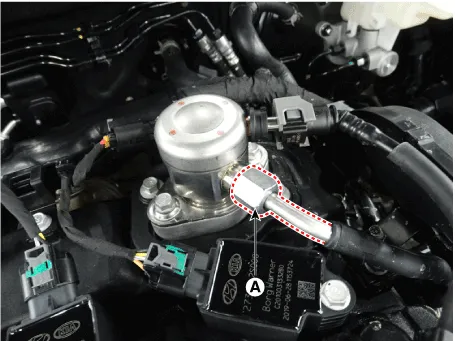

8.Disconnect the injector & rail pressure sensor connector (A).

9.Remove the injector from the delivery pipe (A) after releasing the fixing clip both side as shown below.

1.Install in the reverse order of removal.

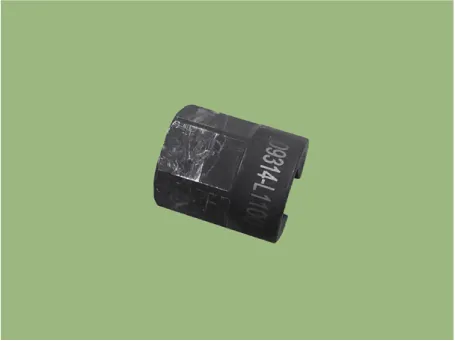

• When tightening the high pressure fuel pipe flenge nut (A), using a SST (SST No. : 09314-L1100).

• Using a spanner torque wrench (27mm).

• Do not reuse the high pressure fuel pipe.

• Note that do not deforming the high pressure fuel pipe.

• Install the component with the specified torques.

• Install the high pressure fuel pipe and then check the oil leakage.

• When Installing the high pressure fuel pipe, using a SST (SST No. : 09314-L1100).

(1)When reusing the injector refer to below.

• When removing/reinstalling the injector, clean the cylinder head hole and the appearance.(Removal of carbon deposits and foreign substances using a brush)

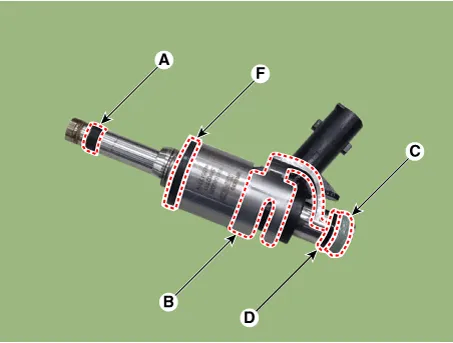

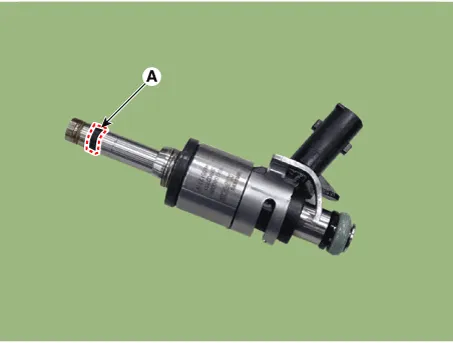

• Be careful not to apply oil/grease/lubricant to the combustion seal (A).

• Do not use the dropped part.

• When inserting the injector, be careful not to damage the injector tip.

• Do not reuse the combustion seal (A), injector clip (B), O-ring (C), support disk (D), rubber washer (F).

• Be careful not to apply oil to combustion seal.

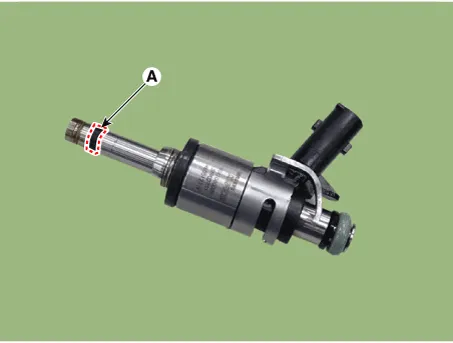

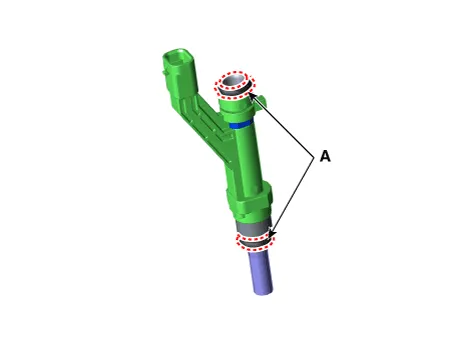

• Do not reuse the O-ring (A).

• Apply the engine oil to the injector O-ring.

• When inserting the injector, be careful not to damage the injector tip.

• In order to prevent from oil leak, replacement of combustion seal should follow the below procedure.

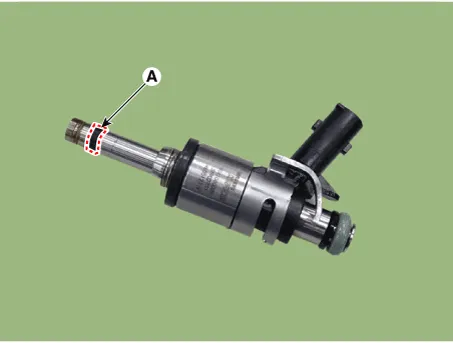

1.Remove the combustion seal (A).

• Be careful not to damage the injector while remove the combustion seal.

• Remove the combustion seal using a nipper.

2.Before the assembly of the sealing ring the groove must be cleaned using a clean cloth.

3.Install the combustion seal using a special service tool (SST No. :09353-L1100).

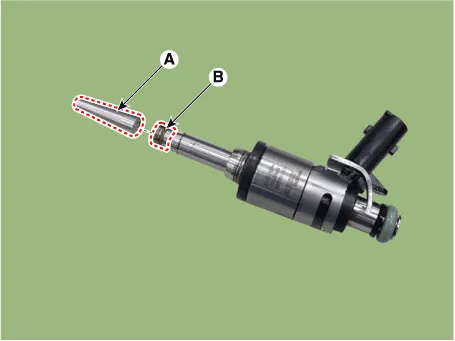

(1)Place the seal installing guide (A) (SST No.: 09353-2B000) on the tip of the injector not to damage the injector tip (B).

(2)Install the combustion seal (A) to the seal installing guide.

(3)Input the seal to A direction of the installer, and push it to B direction until it reaches the combustion seal installation area.

• The complete assembly must not take longer than 2 to 3 seconds.

(4)Install the compressor (A) and disconnect it after rotating 3-4 times to left and right direction.

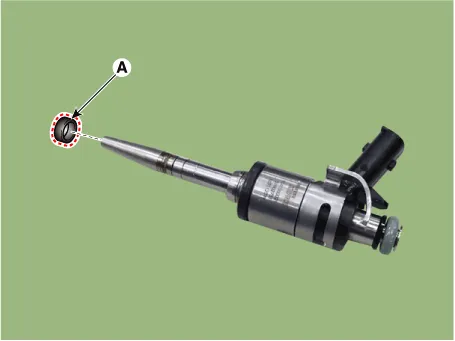

(5)Check the combustion seal (A) installation.

Fuel Tank Pressure Sensor (FTPS)

Fuel Tank Pressure Sensor (FTPS)

- Description

Fuel Tank Pressure Sensor (FTPS) is a component of the evaporative

emission control system and is installed on the fuel tank, the fuel

pump, or the canister. It checks the purge c ...

Purge Control Solenoid Valve (PCSV)

Purge Control Solenoid Valve (PCSV)

- Description

Purge Control Solenoid Valve (PCSV) is a solenoid valve and is

installed on the surge tank and controls the passage between the

canister and the intake manifold.The evaporative ga ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Service Manual: Active Air Flap

- Description

The AAF (Active Air Flap) is located between radiator grille and

radiator.The AAF controls the motor properly and then the air flaps

adjust air flow from the radiator grille.During high speed driving, it

will reduce the air resistance by closing the air flaps. This improves

...

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Fan speed control

Press the button to increase fan

speed and airflow. Press the button

to

decrease fan speed and airflow.

Pressing the OFF button turns off the fan.

Information

Operating the fan speed when the

ignition switch is in the ON position may

cause the battery to discharge.

Air conditioning ...