Hyundai Tucson: Hydraulic System / Valve Body

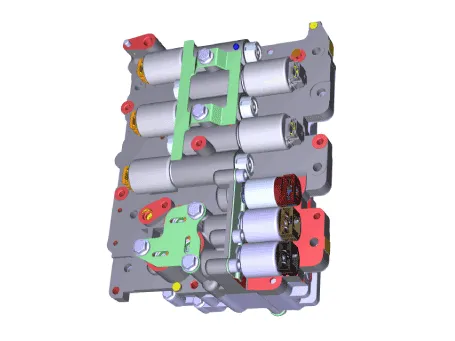

• The valve body is essential to automatic transaxle control and consists of various valves used to control the oil feed from the oil pump. Specifically, these valves consist of pressure regulator valves, oil redirection valves, shift valves, and manual valves.

• The body also features electronic solenoid valves that ensure smooth gear changes.

• Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.(Refer to General Information - "Lift and Support Points")

• When the solenoid valve Diagnostic Trouble Codes (DTC) is on, perform the following procedure to replace it.

• Automatic transaxle is composed of delicate components. Be careful not to cause any damage on the component in the course of assembly and disassembly.

• Maintain clean condition so that foreign substance does not get into the automatic transaxle.

• Use a coated apron, latex gloves, and stainless tray to prevent foreign substance from getting into the transaxle.

• Automatic transaxle fluid (ATF) can be reused. Collect it using a clean 10-liter beaker.

1.Turn ignition switch OFF and disconnect the negative (-) battery cable.

2.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air cleaner")

3.Loosen the wiring bracket mounting bolt (A).

4.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

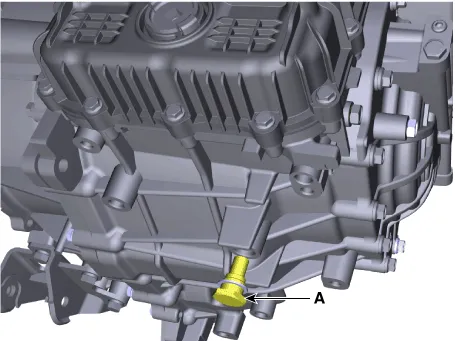

5.Remove the drain plug (A) and reinstall the drain plug after draining ATF totally.

Drain plug tightening torque :33.3 - 43.1 N.m (3.4 - 4.4 kgf.m, 24.6 - 31.8 lb-ft)

• Replace the gasket before reinstalling the drain plug.

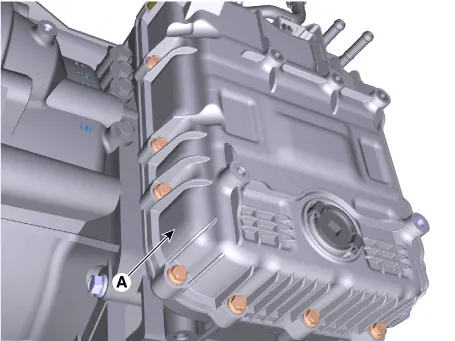

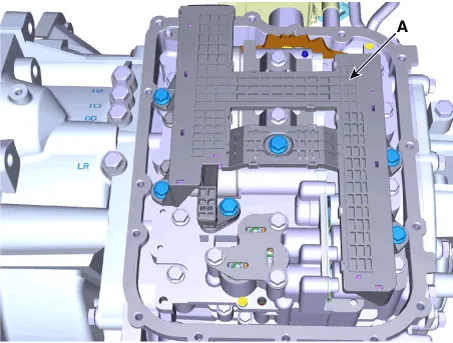

6. Loosen the mounting bolts (A) of the valve body cover.

Tightening torque : 11.8 - 13.7 N.m (1.2 - 1.4 kgf.m, 8.7 - 10.1 lb-ft)

• Be careful when removing the valve body cover because the remaining ATF remains in the valve body cover.

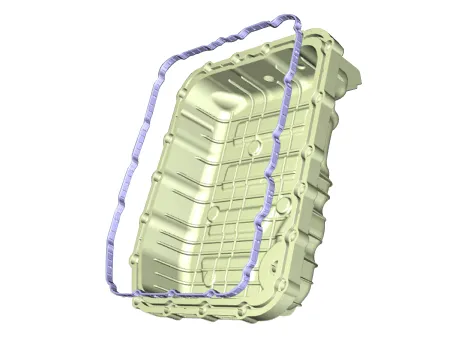

• Replace the gasket (A) before reinstalling the valve body cover.

• After the installation, start the engine and then check if there are any leakages from the valve body cover.

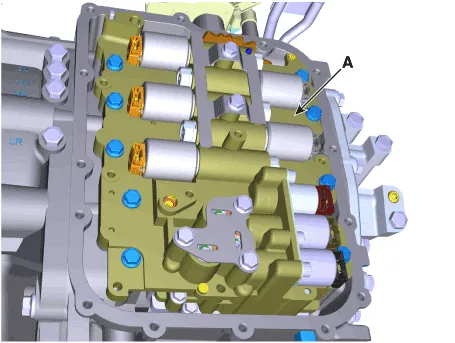

7. Loosen the bolts and then removing the main harness (A).

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

8.Loosen the bolts and then removing the valve body assembly (A).

Tightening torque : (A) 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

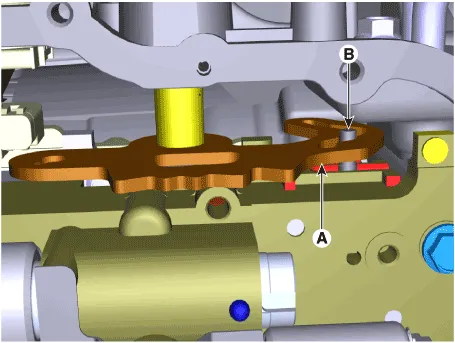

• Attach the manual pin (B) to the detent lever (A) and assemble the valve body.

1.To install, reverse the removal procedure.

• Replace the gasket (A) before reinstalling the valve body cover.

2.Check the ATF level after refilling the automatic transaxle with fluid.(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid (ATF)" )

• After ATF level check or exchange, be sure to remove residual ATF on transaxle case.(Be especially sure to remove residual ATF between automatic transaxle case and valve body cover)

3.Clear the diagnostic trouble codes (DTC) using the diagnostic tool. (Refer to Automatic Transaxle System - "Automatic Transaxle System" )

• Even though disconnecting the battery negative terminal, the DTCs will not be cleared. So, be sure to clear the DTCs using the diagnostic tool.

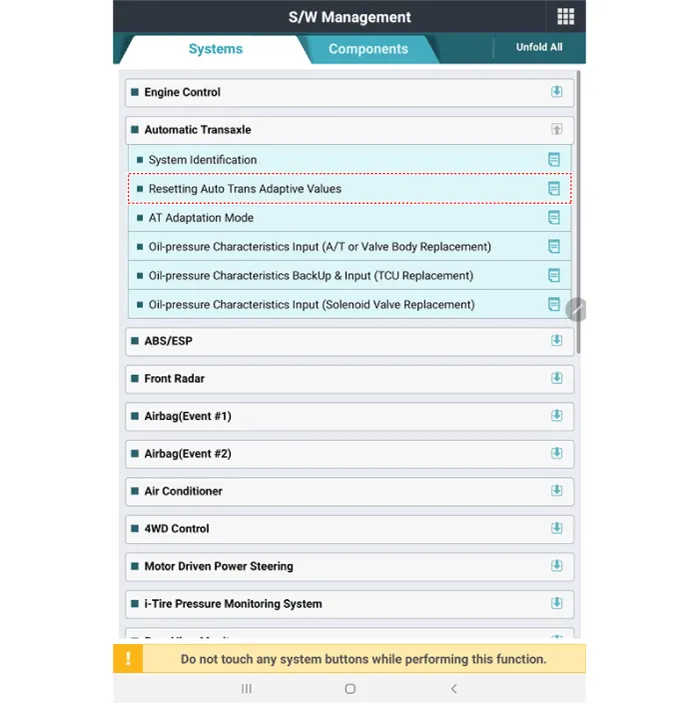

4.Reset the automatic transaxle adaptive values using the diagnostic tool.

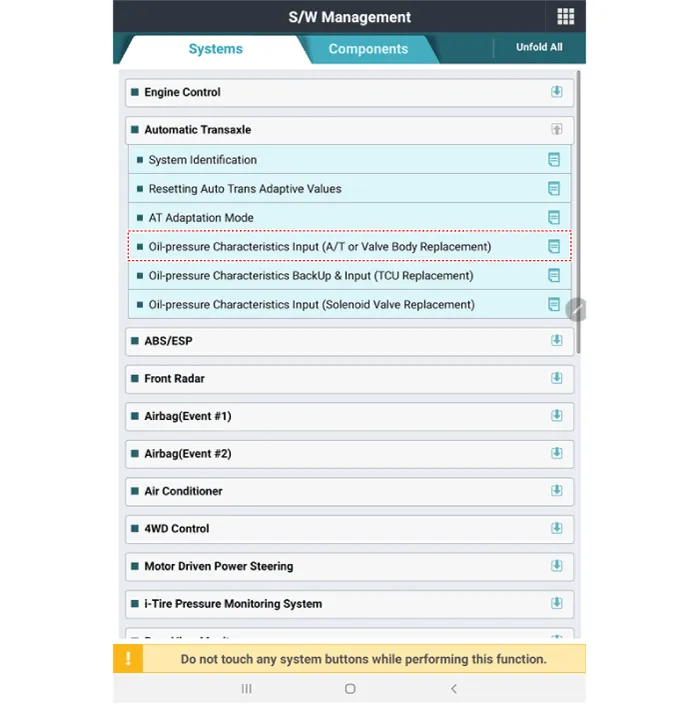

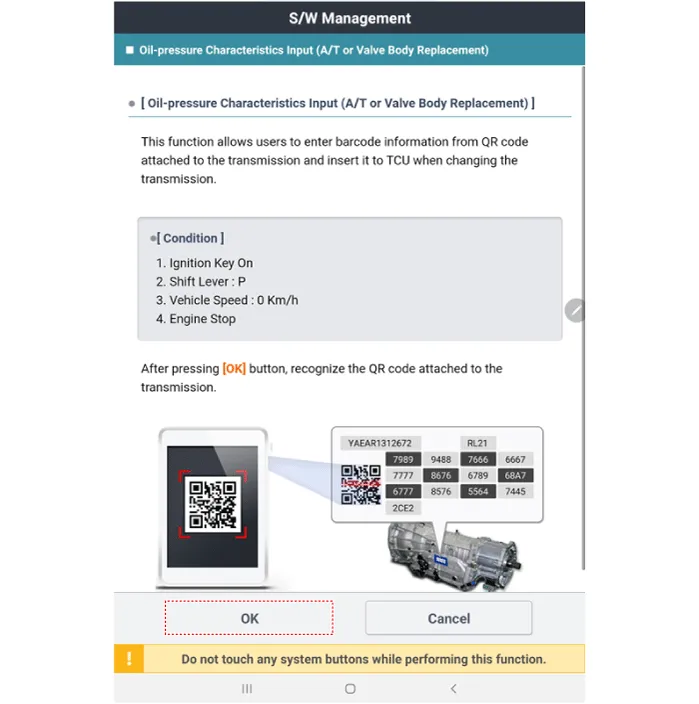

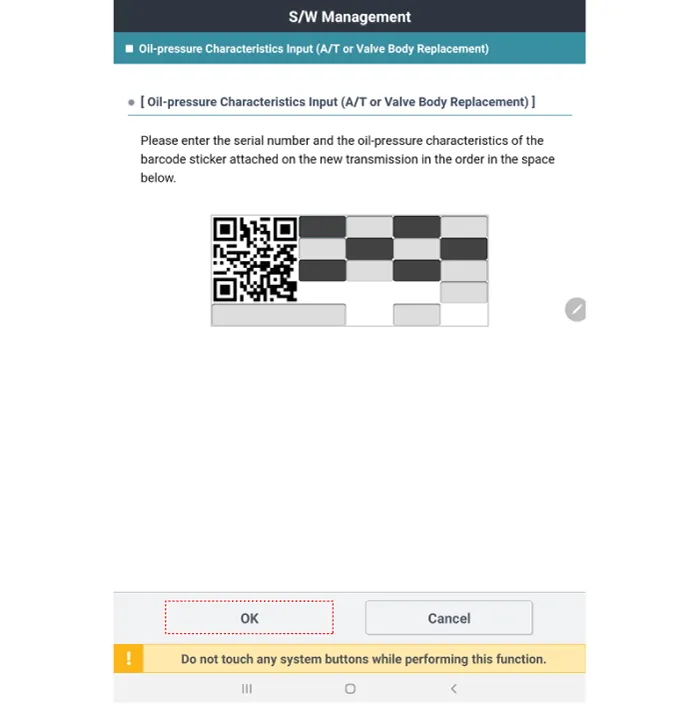

5.Perform the oil pressure characteristics input (A/T or valve body replacement) procedure.

6.Record the bar code data (oil pressure characteristics) on the automatic transaxle case or valve body and then input it manually onto the diagnostic tool.

7.Perform the TCM adaptive values learning procedure.(Refer to Automatic Transaxle Control System - "Repair procedures")

8.Be sure to check for leaks in each connection part when the engine is started.

Electronic Oil Pump (EOP)

Electronic Oil Pump (EOP)

- Removal

1.Turn ignition switch OFF and disconnect the battery negative (-) terminal

2.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

3.Disc ...

Torque Converter Clutch Control Solenoid Valve (T/CON_VFS)

Torque Converter Clutch Control Solenoid Valve (T/CON_VFS)

- Description

• Torque converter control solenoid valve (T/CON_VFS) is attached to the valve body.

• This variable force solenoid valve indirectly controls the hydraulic pressure inside the ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Service Manual: Oil Filter & Oil Cooler

- Removal and Installation

• Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when raising

the vehicle using the lift.(Refer to General Information - "Lift and

Support Points")

1.Remove the engine r ...

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Securing a Child Restraint System

with the LATCH Anchors System

To install a LATCH-compatible Child

Restraint System in either of the rear

outboard seating positions:

1. Move the seat belt buckle away from

the lower anchors.

2. Move any other objects away from

the anchorages that could prevent

a secure connection between the

Child Restraint System ...